|

Hg-free Solid State LightingCurrent light sources use the 254 nm emission of electrically excited Hg to excite phosphors coated on the inside of lamps to emit visible light. The development of alternative solid state lighting sources have been driven mainly by environmental reasons to replace Hg with other sources (e.g. Xe, Ar, Kr) that emit in the vacuum ultraviolet (VUV) region. Considering the larger energy gap between VUV excitation and visible emission levels, the overall efficiency of visible light generation using conventional lamp phosphors is reduced. Therefore, quantum cutting phosphors that emit more than one visible photon per absorbed VUV photon are employed to improve efficiency of visible light generation. The optical properties and efficiency of phosphors are tailored by controlling the rare-earth luminescent dopants and co-dopants, activators, and host matrix. |

|

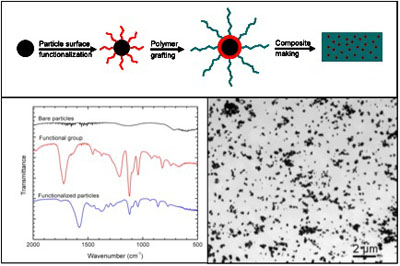

Biodegradable ImplantsBiodegradable implants with appropriate initial strength and stiffness with controlled degradation rates (based on bio-absorbable polymers or composites) can be advantageous over the metallic implants in orthopedic applications. The objective of this work is to develop a composite biomaterial consisting of ceramic/metal nanoparticles reinforced biodegradable polymer. |

|

Mixedness DeterminationA variety of ceramic, pharmaceutical, cosmetic and food products are fabricated by powder processing. The distribution of each powder component in a mixture controls many of the properties of the resulting material. If there is a lack of chemical uniformity (mixedness) in the starting mixture of a ceramic, the sintered body may contain an increased number of defects such as pores, inclusions, or differences in phase composition. Rare earth-doped ceramics rely on the proper distribution of dopant ions to optimize fluorescence properties, due to the effect of dopant distribution on bulk radiative decay time and quantum efficiency. As rare earth ions cluster, their proximity induces concentration quenching, which decreases the radiative decay time and quantum efficiency of a bulk sample. Concentration quenching typically occurs for ion spacing less than 1 to 10 nm, which is a function of the host and dopant materials, as well as other chemical bonds to the dopant. The bulk radiative decay time is a function of all nanoscale ion interactions, so it is crucial to optimize chemical homogeneity on the nanoscale to improve bulk properties. We are studying the effect of particle size distribution and methods of mixing on the chemical homogeneity of rare earth-doped ceramics both computationally and experimentally. |

|

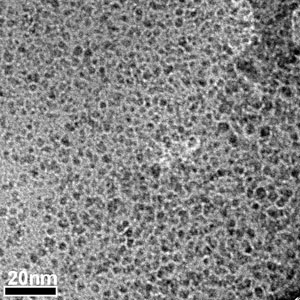

Upconverting Nanoparticles for Biological Imaging & Tissue EngineeringThe ability to image cells in vivo is an extremely valuable tool as a diagnostic reporter of biomedical pathologies and mechanisms. Currently used labels for biological imaging are organic dyes, proteins, and quantum dots, which have many drawbacks. Many of these rely on "downconversion", which occurs when a material absorbs a photon of higher energy light (in this case, ultraviolet) and emits a photon of lower energy light (visible). Cells and tissues absorb ultraviolet (UV) light, which causes unwanted background fluorescence, and raises concerns of phototoxicity. In contrast, upconverting nanoparticles involve the absorption of two or more low energy photons (in this case, near infrared) to emit one higher energy photon (visible). My current research involves synthesis, characterization, and surface modification of upconverting nanoparticles for biological imaging and other tissue engineering applications. |

|

Hydroxyapatite SynthesisThe overall motivation behind the research has been the failure of current implant options to withstand the mechanical and biological demands for the remaining patient lifetime. There is a growing demand for osteoimplants to exhibit high osteoinductivity and positive biological response, but in the same measure, provide mechanical properties closer to what is seen in native bone. While all these objectives may eventually be met, during implant design, it is important to look at how nature forms the material—the conditions, resulting microstructure, and chemistry.

|

|

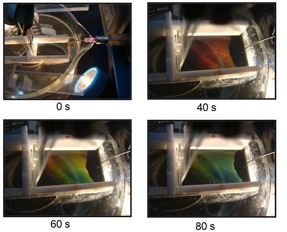

Fluid FormingWe have demonstrated the preparation of single-crystal-like materials using Fluid Forming. Fluid Forming is the patented method to self-assemble surface-modified particles on air-liquid interface and lift-off the assembled monolayer. Since Fluid Forming was developed, a lot of efforts have been taken to improve the process and currently we are focusing on the development of continuous Fluid Forming process which can cover the area of 50 cm2 in several minutes with densely packed monolayers of nanomaterials. This figure shows that self-assembly of nanoparticle is in progress, and diffracted color depends on particle size, interparticle distance and film thickness. |